Logistics management often looks like a tangle of spreadsheets, email chains, and carrier portals. Hardly the reliable backbone that operations teams need. You try to check a spreadsheet on your phone and end up pinching and zooming through endless rows. But without any visible timestamps or change history, you’re never sure whether the figure before you changed five minutes ago or hasn’t moved in days.

“Rates in logistics are the worst part. There is no international standard; each country has its own extra charges, and all the carriers provide the rates in their own format. This makes it hard to keep track of the changes in the rate fluctuations and reduces the ability to provide quick quotes to customers.”

Thais Fontes

Business Analyst at Synergie Canada

That lack of real-time visibility derails workflows across your supply chain. Untracked inbound delays bring production lines to a standstill, drive up costs, and cause issues with the customs clearance of goods. Outbound deliveries don’t have proper status updates, leaving your support team to field numerous customer calls for information.

Spreadsheets, often the default logistics solution, can’t keep pace. They demand manual updates, break under complex formulas, don’t scale, and become nearly impossible to use when you’re away from your desk, exactly when you need them most. Single editor access makes collaboration within Excel challenging. Tariffs, weather disruptions, geopolitical shifts, and labor shortages cause supply chain disruptions and deepen the uncertainty.

Off-the-shelf logistics software solutions rarely align with your specific needs, but are extremely costly nonetheless. They often lack critical integrations with your existing systems, don’t accommodate your unique workflows, or force significant compromises in how you operate. You end up logging into multiple platforms to try to get a complete picture.

Custom logistics software changes that. It brings all your data together (inbound and outbound shipments, inventory transfers, vendor handoffs) into a single, operational view. It adapts to your existing workflows, and delivers the real-time visibility you need—at your desk or on the go—so you can spot issues before they become crises.

Here’s what that visibility actually looks like in practice.

1. Track every shipment in one place across vendors

For all inbound and outbound shipments

Custom logistics software brings all your shipment data into a single dashboard, giving operations and warehouse management teams real-time visibility across your supply chain.

Tracking shipments typically means piecing together updates from multiple sources. Your purchasing team checks supplier portals for inbound materials. Your logistics team monitors carrier websites for outbound deliveries. Your warehouse staff updates spreadsheets when items arrive. Vessel and container tracking services provide live location and travel data. None of these systems talk to each other, creating information gaps that lead to frustration.

Custom logistics software synchronizes with carriers’ systems automatically by using their APIs to import tracking numbers and delivery estimates, while also extracting shipment details from confirmation emails. It’s also better for PO management, since it allows the logistics team to know in advance when the purchasing team has goods ready to ship. Logistics can make more informed decisions about whether to bundle items together or ship them separately.

Instead of asking “Has that order shipped yet?” or “Where are those materials I need today?” Everyone from executives to warehouse staff can check their app and immediately see what’s moving, what’s delayed, and what needs attention from their own perspective.

This means you can notify customers about issues before they reach out, adjust staffing if inbound supplies are behind schedule, or reschedule work when a delivery stalls. Instead of scrambling for answers, everyone who needs to know can check the latest third-party carrier updates from any device, right alongside your internal shipment records.

This unified view becomes particularly valuable for businesses that need to manage both inbound and outbound shipments. Take a construction company sourcing raw materials from different vendors and shipping them to multiple job sites. With everything unified in one interface, project managers can see that one delivery arrived on schedule, while a late shipment of concrete mix means the schedule needs adjusting.

No more hunting through siloed data—just one place to check every order’s status and act before small issues become costly disruptions.

2. Choose the right carrier based on estimated costs

For businesses comparing multiple transportation options

Picking the most cost-effective carrier shouldn’t mean sorting through spreadsheets and inboxes. A custom rate estimator handles the comparison for you, automating freight cost analysis so your team can make smarter decisions, faster.

“We've built custom calculators for some clients. These help them understand the total amount of our rates without the need for them to request a quote each time, reducing the amount of emails and increasing the number of approved bookings.” - Thais Fontes, Business Analyst at Synergie Canada

The software solution can pull past invoices or uploaded rate sheets, sync with carrier APIs, or parse new quotes directly from email. If live data isn’t available, the tool falls back on stored rates to keep estimates accurate. You can import a shipment label to auto-fill weight and destination, and the app instantly analyzes cost based on route, delivery speed, and historical trends.

You can layer in carrier performance data—like reliability, delivery speed, or past performance—to make more informed decisions. For example, a craft brewery sending weekly kegs to bars compares refrigerated freight rates side by side. The estimator shows which carrier delivers at the lowest cost, and they cross-reference this with on-time delivery data so they book the best delivery option in seconds.

3. Get a real-time view of internal stock movements

For transfers between warehouses, stores, job sites, or other company-managed locations

Whether you’re sending products from a central distribution center to regional warehouses, transferring goods from a warehouse to retail stores, or moving raw materials out to a construction site, a custom logistics app shows your team exactly where every item is—and when it arrives.

Instead of relying on email threads or manual handoffs, teams can create transfer requests directly within the app. Each request logs movement details automatically, pulled from barcode scans, dispatch logs, or internal order forms, so the system always reflects reality.

When you connect your logistics software to other systems, like inventory management software, warehouse management system, Enterprise Resource Planning (ERP) software, or even a spreadsheet, it adjusts stock counts across these platforms in real time. That instant, synced tracking replaces double entry and reduces the risk of a team missing updated or mismatched records.

Everyone from office staff to on-site crews can see what’s pending or delivered right from their phones.

Advanced chemistry company CarboNet uses custom software to track its assets. With different teams using disconnected spreadsheets, it constantly encountered data mismatches and operational inefficiencies. Now, its finance, commercial, and field teams all use a single, mobile-accessible app to track assets, update records, and keep operations aligned.

4. Coordinate drivers and manage your own fleet more efficiently

For businesses with in-house transport teams or partial fleet ownership

If drivers can’t update delivery status, report issues, or get instructions while they’re on the move, you lose visibility and your fleet slows down. A mobile-optimized logistics app gives drivers the real-time tools they need on the road.

Drivers can access location-specific delivery instructions, like which loading dock to use or areas to avoid. This prevents confusion at the drop-off site and keeps the fleet moving without delay. They can also upload photos or voice notes, which are automatically saved to the delivery’s history, which is useful for flagging issues or capturing important details for future reference.

As vehicles move, the app uses real-time location data to automate fleet status updates. It detects when a driver arrives at the location, when the vehicle is delayed, and when the truck is on the move after completing a delivery, all without needing manual input.

Dispatchers and managers track it all live through a transportation management dashboard. A real-time, map-based overview of the entire fleet allows them to monitor vehicle progress, optimize routes, and respond to delays immediately. Every update keeps delivery records and operational data accurate down to the minute.

That’s how logistics company Innovative Logistics Group keeps dispatchers and drivers on the same page. They built a transportation management system with Glide that gives both teams better visibility and coordination throughout every delivery.

“It's a powerful application,” said Adam Wingfield, Founder/Managing Director, Innovative Logistics Group, “We’re seeing it save time for everybody in the process. User error has been completely eliminated, and because we’ve been able to limit that, our efficiency has improved, our accuracy has improved, and it’s improved our level of customer service to the end user.”

5. Bring visibility to reverse logistics and returns

For businesses managing returns, repairs, or restocking across multiple locations or partners

When return workflows are visible and flexible, you stop losing time, inventory, and money. A custom logistics solution lets your team track returns, repairs, and restocks across every location without relying on rigid ERP rules or back-and-forth emails.

Returns often fall outside the systems built to track outbound deliveries or incoming shipments. There may not be a clear owner, the process varies by team or site, and updates get buried in emails or forgotten entirely.

With a custom tool, you can build return workflows that match the specific way your business works and make it easy for anyone to log a return directly from a phone or tablet.

A technician can flag equipment that’s worn down after weeks of use and upload a photo to request a repair. A site manager who receives the wrong item can assign it for return to the supplier. A crew member with leftover cabling can log it for return to the warehouse, where it’s inspected and added back to inventory. Each return is tagged with a reason and automatically routed to the right next step, so nothing stalls or goes undocumented.

This is especially valuable when returns don’t follow a standard path. A construction crew sending tools back from a site doesn’t need the same workflow as an e-commerce store receiving returns from customers.

Tracking the returned items is automated at every step, from pickup requests to delivery at the final destination. Over time, it also surfaces patterns—repeat errors, delays, or missing items—that help you tighten processes and reduce costs before problems accumulate.

6. See performance and cost data without digging through spreadsheets

For all businesses to get a clear view of logistics costs, vendor performance, and operational efficiency

Logistics costs are never static, especially when you use different vendors and carriers, or your business operates across multiple regions. Custom logistics software brings together all your logistics costs and performance data in one view, making it easier to make smart, data-driven decisions.

“The cheapest rate isn’t necessarily the best for your clients. You need to understand their needs. We often see clients who value a more reliable service or a better transit time over price. Having all our rates and quotes in one place enables us to keep track of how to quote that client better in the future.” - Thais Fontes, Business Analyst at Synergie Canada

Your custom app is already pulling data like fuel spend, delivery costs, vendor reliability, or on-time rates from multiple sources and for different reasons. Dashboards let you track all this data in one place instead of switching between different platforms.

You can add filters or custom views to break down the data by region, carrier, delivery type, or time period, helping you quickly spot trends or outliers. If fuel costs spike on a certain route or a carrier’s on-time rate drops, you’ll see it right away and can take action before small issues become bigger problems.

For example, a fulfillment manager filters on-time carrier data and finds that one vendor’s shipments arrive with more consistency than others. The team starts routing more critical inventory through that vendor to improve reliability.

7. Keep track of SOPs

For all businesses

Lastly, if you’re using Excel, it can be incredibly challenging to keep track of clients’ SOPs across all the different teams: quoting, booking, tracking, documentation, and invoicing. A custom app can serve as an easy knowledge management system, keeping critical documents and details at your team’s fingertips at all times.

What does a good custom logistics software look like?

No off-the-shelf tool is going to fit your exact operation. A good logistics software solution should reflect how your team actually works—across devices, roles, and locations—and give you the flexibility to adapt as your workflows shift.

Here’s what to look for.

- Real-time visibility—Your team should be able to track shipments as they move, not rely on yesterday’s data. The software must offer clear, immediate visibility through dashboards, maps, or lists that update in real time. This means you can answer questions about shipment status instantly, without having to chase down information.

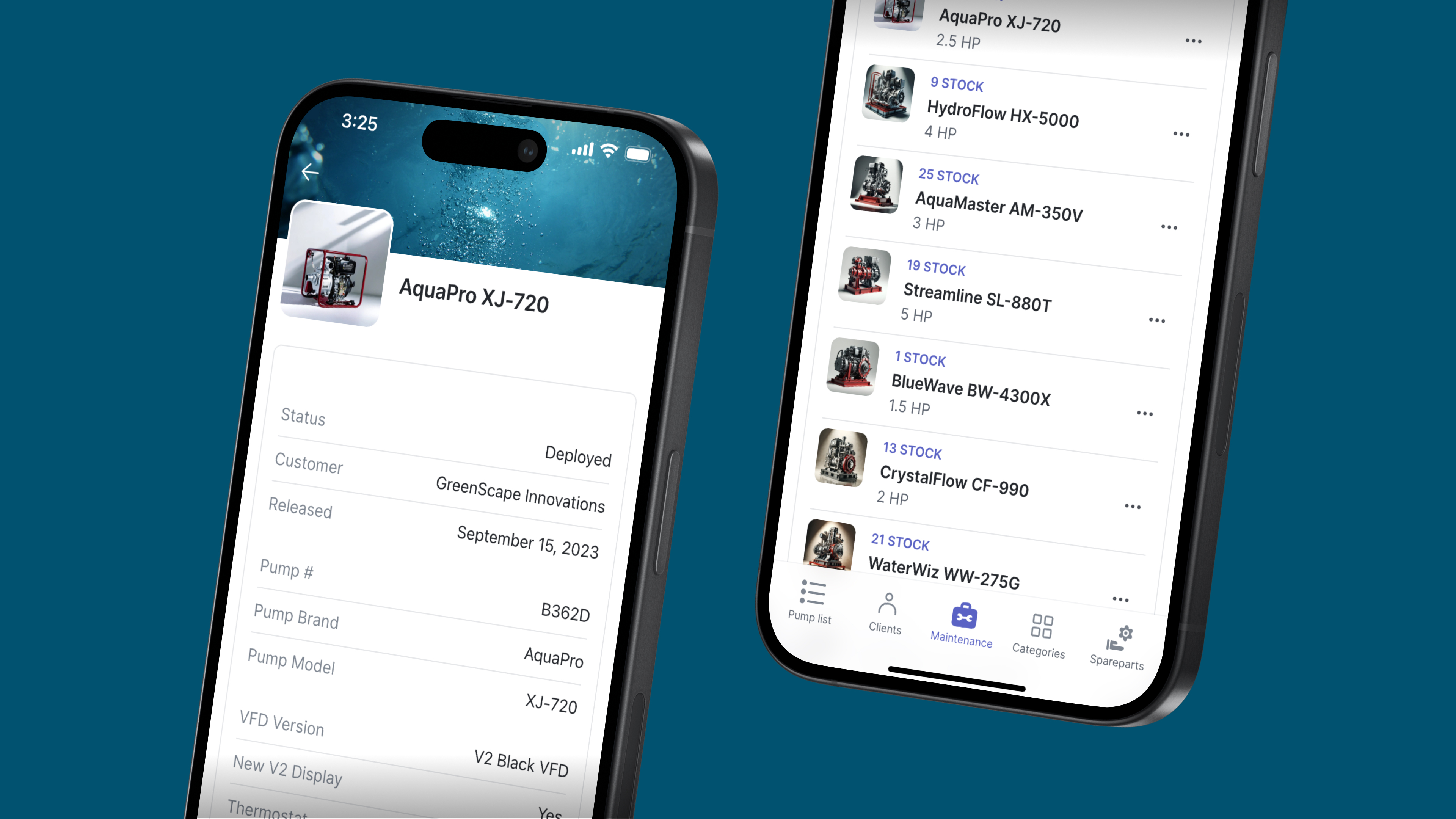

- Mobile accessibility and optimization—Because your team is often on the move, whether they’re drivers, field technicians, or managers visiting sites, the software solution must work seamlessly on phones and tablets. A design that adapts to any screen size means everyone can access information and make updates easily, even on a mobile device in a busy environment.

- Flexible integrations—Not every carrier offers a full API, and not every vendor runs on the same system. Your logistics software should pull data from wherever it lives—carrier portals, spreadsheets, email confirmations, databases, or ERPs—and update when live connections are available. While the goal is to minimize manual entry, the system should still allow for it when APIs aren’t available or quick updates are needed. It should also connect with AI agents to trigger workflows, exchange information, or automate tasks based on agent-driven insights.

- Two-way data exchange—It’s not enough to just pull data into your custom software—it should also be able to push updates back to your connected systems. This two-way sync keeps all your records consistent and accurate across platforms without requiring manual entry.

- Adaptable to different users—A manager tracking regional performance and a technician logging damaged goods aren’t doing the same job. A good system supports both while keeping the workflows simple. The user interface needs to be intuitive and straightforward for all skill levels, making it easy to learn and efficient to use.

- Role-based access—You may need to control who can see specific data and perform certain actions to protect sensitive business information and prevent accidental errors. Clear roles and permissions also simplify the software for each user, showing them only the features and data relevant to their tasks, which makes their job easier and more focused.

- Customizable dashboards and views—Each team member should be able to quickly find the shipments, updates, or reports that matter most to their role. Customizable dashboards, filters, and saved views allow users to tailor their experience, so they spend less time searching for information and more time acting on it.

Learn how a leading Glide agency is powering clients’ operations with AI

Read the interviewHow to get custom logistics software for your business

The traditional path of custom coding your own app can certainly deliver a tailored solution, but it often takes months of development and requires dedicated engineering resources. This requires a significant and ongoing investment of time and money. Instead of committing to a long custom software development cycle, many businesses are choosing more flexible software solutions that they can shape themselves.

Platforms like Glide let your teams build and adjust your own custom logistics software without writing code. Unlike spreadsheets, custom apps are adaptable and multiplatform, allowing you to work across a computer, tablet, or phone fluidly and easily.

With this approach, you typically have a few ways to get started. You can often begin with a pre-built template and customize it, build your app from scratch using drag-and-drop components, or, if you prefer, hire an experienced Expert to consult on your needs and get your software launched fast.

Each option gives your team full control over how your custom logistics software fits your operations and the freedom to change it as you go, without waiting on anyone else.